If you’re feeling the lockdown weight piling on you might be happy to know you’re in good company, there is someone else with a looming weight problem: Heavy Goods Vehicles .

It isn’t good enough for heavy haulage vehicles (HGVs) to just move heavy things around – they also need to be able to stop heavy things moving around, when needed.

Maximum weight carry limits for HGVs are carefully controlled for safety reasons. Overweight loads increase the stopping distance and decrease stability. This why you occasionally see big rigs pulling a near-empty trailer – look closely and you will notice the cargo will be something very dense, like a roll of copper, or a large engineering part.

It’s all down to a pretty simple equation: the more mass, the more kinetic energy that has to be overcome for a vehicle to come to a stop from a given velocity. Add more mass, and stopping distance must increase.

Well, that’s basic physics, so where is the problem coming from?

Despite the bluster of some battery electric vehicle (BEV) manufacturers (**cough, cough** Elon), there is a very real reason why long-range BEV HGVs have yet to materialise: long range means more batteries… a lot more.

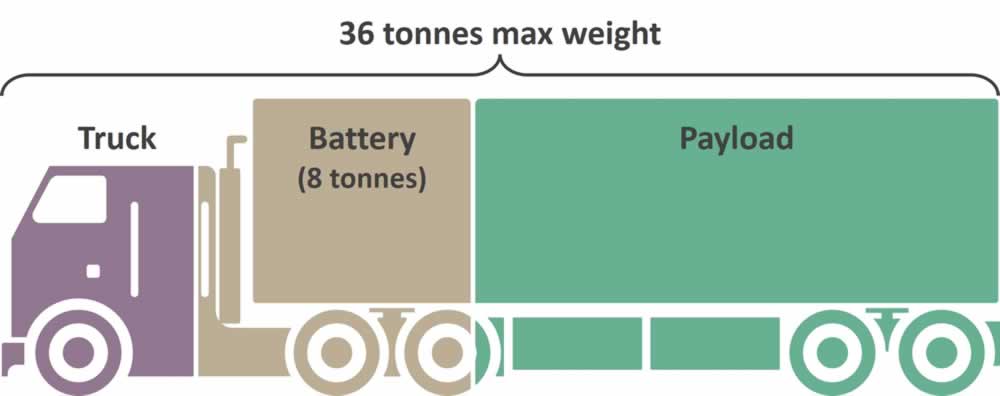

And batteries are very heavy. Estimates suggest that long-haul HGVs would need about 8 tonnes of lithium batteries to achieve the kind of range offered by diesel or hydrogen fuel cell equivalents. To accommodate the additional weight of the batteries, at least 10 pallets of goods have to be taken off the truck.. This translates to less cargo per trip – a loss of revenue.

It isn’t clear if the BEV providers are trying to gloss over this fact for marketing, or if they’re simply scrambling for solutions out of the public eye. Maybe they know batteries are not a realistic proposition for heavy haulage, but they cannot be seen not to be responding to public demand? Either way, this looming weight problem is one of the reasons why heavy goods transport is unlikely to use battery technologies in the future.